Seamlessly Shipping all over Pakistan.

Orthodontic treatment is essential for correcting misaligned or crooked teeth, and clear aligners offer an effective alternative. Also known as invisible aligners, these aligner trays are custom-built for each patient, depending on the severity of teeth misalignment or malocclusion.

Unlike traditional braces, clear aligners are virtually invisible and can be easily removed, allowing for maximum convenience and flexibility. Clear aligners are not only easy to maintain but also offer better aesthetics, making them a popular choice among patients. As the demand for clear aligners is growing, it is important for practitioners to offer this alternative treatment to their patients.

This first step consists of taking the dental impression of the patient, either with alginate – which will be used to make the plaster model and then scanned with a desktop 3D scanner – or with an intraoral scanner, a much modern approach recommended to keep a fully digital workflow and save considerable amount of time.

Aligner offers a simplified base for the scanned models which is adapted for a cost-effective 3D printing. For other uses, Deltaface offers the arch base module.

Aligner offers a simplified base for the scanned models which is adapted for a cost-effective 3D printing.

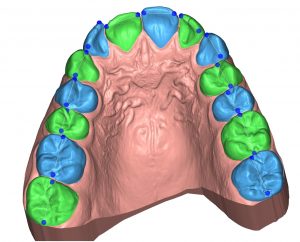

AN ACCURATE AND FAST TOOTH RECOGNITION

This step is essential for the software so that it can identify the gum and each tooth. The user enters the mesial and distal points of each tooth to be moved, the rest of the operation is fully automated. An adjustment of the contour of each tooth remains possible.

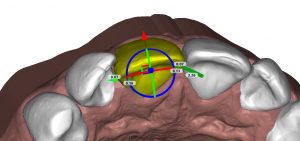

This step determines the origin of the angles and the movements of each tooth. It also allows to precisely adjust the axis and the center of resistance of the teeth. A virtual root is added.

A panoramic X-ray of the teeth or a Cone Beam (CBCT) might be useful for an accurate adjustment.

Setup is the most important step in the alignment process. It consists in virtually moving the teeth to the intended outcome. The software gives you complete control over the treatment plan for advanced customisation of each case. The number of aligners to reach the goal is calculated in real time with each new movement. Maximum movement values are adjustable for each tooth, depending on different parameters, such as the patient’s age or the elasticity of the aligners. Complex movements can be accelerated by adding attachments, stripping (IPR) is therefore simulated. Occlusion and collisions can be controlled in real time. It is also very easy to introduce independent sequences to manage for example a prior distalisation or an over-correction. So, to avoid any confusion, a 3D engraving systematically includes the step number.

The treatment plan with stripping data, attachments positioning and movements are displayed in an animated layout. A detailed digital report includes all this information in a PDF format.

The thermoforming technique is the reference technology to produce the aligners. It consists in printing a model for each step of the treatment, thermoforming a plastic sheet, which will be then trimmed and polished.

Consequently, Aligner exports information to automate the process of trimming the aligners after thermoforming that can be used with WorkNC Dental© software among others.

Direct 3D printing of aligners is more innovative and is gradually gaining market share, especially with the emergence of more suitable resins. It is a major breakthrough in the field of invisible orthodontics and we are sure that in a few years this technique will be widespread because it offers many advantages notably: better precision, saving of time by eliminating the steps of thermoforming, cutting and polishing; it also allows a saving of resin by eliminating the need to print the models, which has an ecological virtue.

With its partner Graphy, Aligner has introduced functionalities specifically adapted to aligner resins. For example, it enables to set the rigidity of the aligner by locally adjusting the thickness of the aligners.

At Sky Heights, we specialize in innovative 3D printing solutions and high-quality accessories. Our mission is to bring your ideas to life with precision and creativity, offering cutting-edge technology for a wide range of applications. Whether you’re a hobbyist or a professional, Sky Heights has the tools and expertise to elevate your projects to new heights.