No products in the cart.

Seamlessly Shipping all over Pakistan.

Precise resin 3D printers are used by jewelers to speed up and automate a traditional investment casting process.

Two techniques have historically defined jewelry making: handcrafting and lost-wax casting. Both techniques require significant technical expertise, are highly time-intensive, and mistakes in the process can prove expensive.

But today, digital design and 3D printing are primed to disrupt these age-old practices in a major way. Supplementing traditional processes with digital techniques brings new possibilities in design and production to jewelers, as well as exciting new customization options for customers.

The process described above is traditional jewelry making. 3D Printing is the best and most economical way to create 3D-printed jewelry. It will produce a real, solid piece of jewelry with a smooth surface. Depending on your wishes, the object can also be finished manually with post-processing.

Using the traditional casting process, jewellery designers will hand-carve the original pattern in wax followed by placing the wax pattern in a mold to be burned out. To create the cast piece, melted metals like the gold and silver will pour into the mold cavity. Upon getting the cast piece, designers will polish the cast piece to the type of finishing of the end product.

Using 3D printing, jewellery designers make use of CAD software (eg. Matrix) to create their jewellery design digitally and 3D printed out their patterns using 3D printer that can be used for casting direct to create the mold. The after process of creating the cast piece will be the same as the traditional casting process.

With no minimum order of quantity, you can start offering bespoke personalize creations as part of your unique value add to your customers using digital tools for designing and 3D printing to either direct 3D printing them in plastic/metal or create the wax patterns for casting.

The benefit of using 3D printing is the great time-reduction from designing process to produce the patterns.

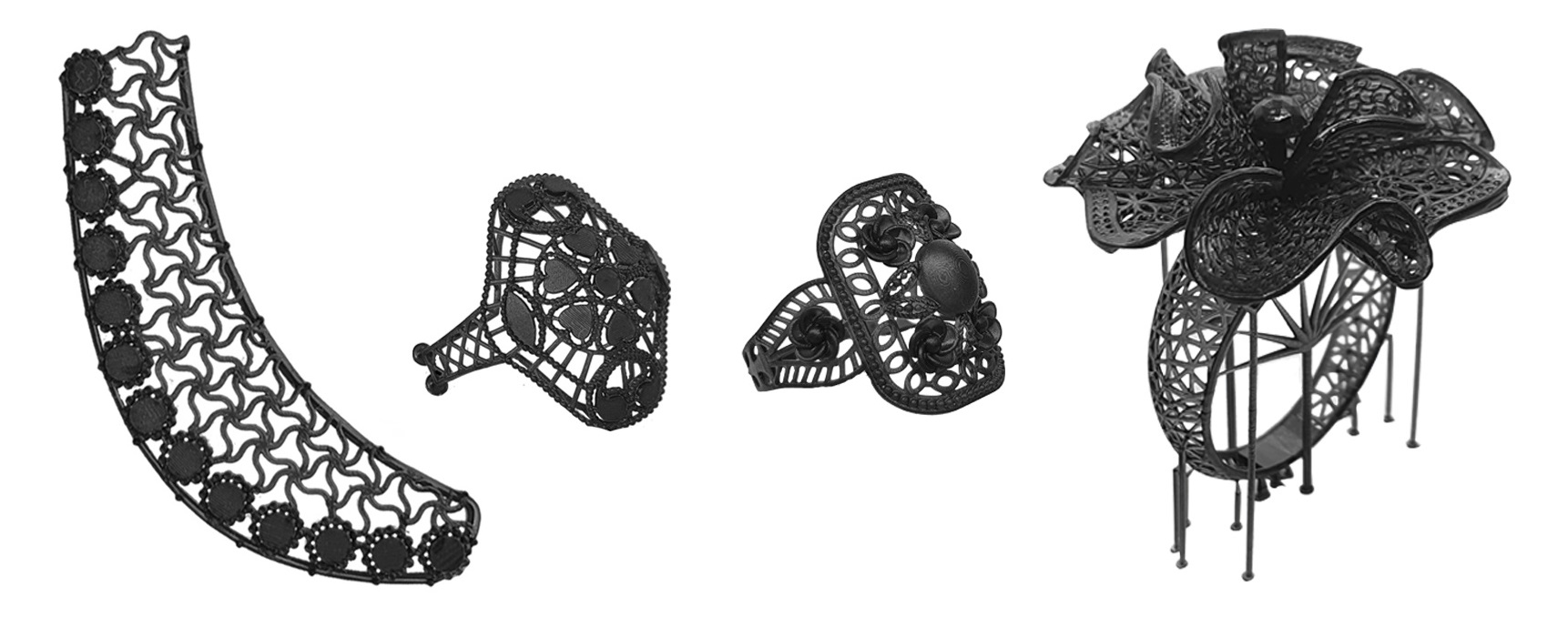

With the help of 3D printing, you can create complex designs on your jewellery using designing software that is difficult to hand-carved in the traditional methods. With the advanced 3D printing technology, you can 3D print complex jewellery using castable resins, master pattern material or print in wax from 3D Systems used on ProJet MJP 2500.

You can direct 3D print your jewellery in metals such as Brass, Bronze or Silver with different plating options on the finishing.

Alternatively, you can also 3D print using castable resins, master pattern material, print in wax or print in nylon using the SLS Technology.

The beauty of 3D printing is you can control how you would like your design to be printed out. You can print in 100% fill for strong and heavier feel; if you want it to be lighter, you can try 80% fill or lesser depending on the requirement. You can also design your jewellery with lattices structures.

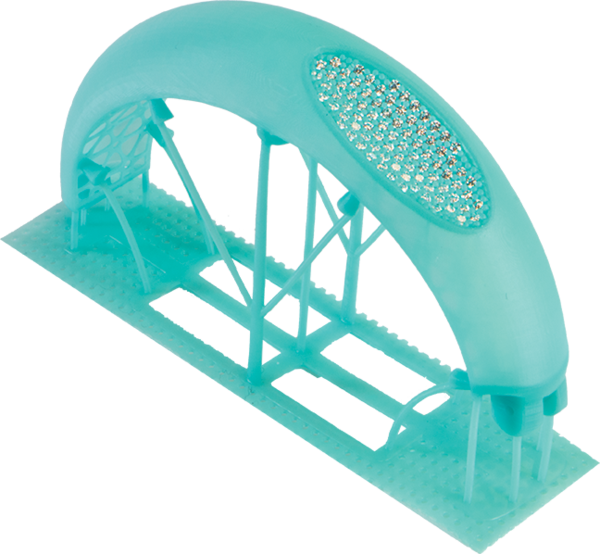

Jewelers can implement resin 3D printers following four simple steps. Here’s how it works.

Multiple iterations of a design are 3D printed with standard resin.

3D printed models are used for fitting and gathering customer’s feedback.

Castable resin is used to 3D print an investment pattern of the final design.

The pattern is used to make a mold for the target material.

At Sky Heights, we specialize in innovative 3D printing solutions and high-quality accessories. Our mission is to bring your ideas to life with precision and creativity, offering cutting-edge technology for a wide range of applications. Whether you’re a hobbyist or a professional, Sky Heights has the tools and expertise to elevate your projects to new heights.