No products in the cart.

Seamlessly Shipping all over Pakistan.

₨ 20,000 Original price was: ₨ 20,000.₨ 15,000Current price is: ₨ 15,000.

● Water Washable & Slight Odor

● Low Viscosity, Fast Printing

● High Precision & Low Shrinkage

● Eco-friendly

Your orders are shipped seamlessly between cities

You can return your orders within 5 days.

Your payments are free & secure with us.

________________________________________________________________________________________________________________________________________________

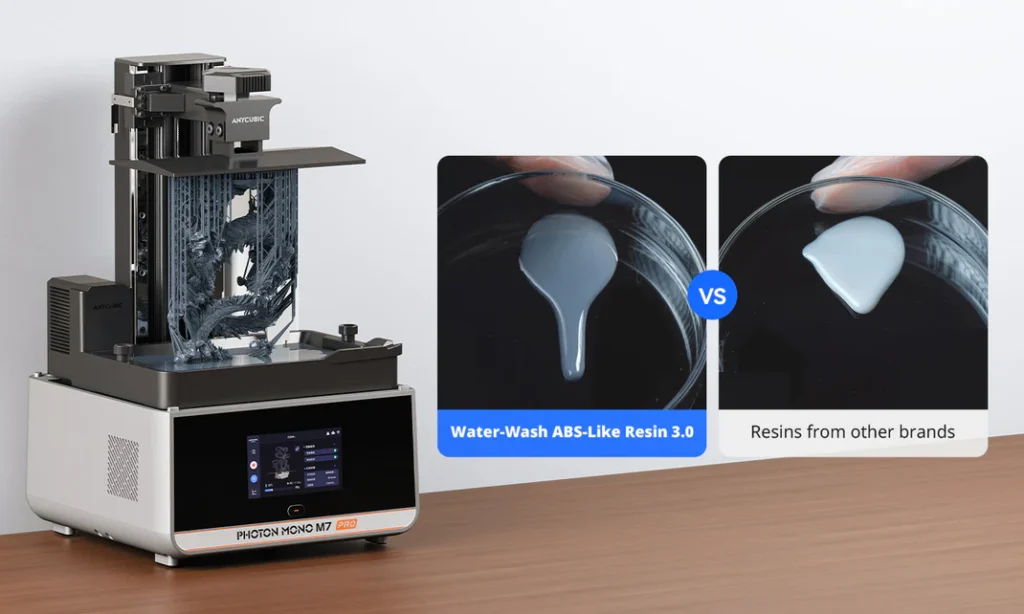

Enhanced with hydrophilic agents, you can now wash off the residual liquid resin with water, reducing post-processing duration and costs. Thanks to the water-washable formula, the cured prints exhibit minimal shrinkage rates and are less prone to cracking

It is ideal for applications such as prints that require drilling ortapping, load-bearing parts, and miniature figurings.

*Easy support removal for delicate parts

Toughness x2: Impact-and crack-resistant exhibit minimal shrinkage rates and are less prone to cracking

High levels of detail that make prints come alive

Precisely duplicate design dimensions to ensure minimal assembly tolerance.

With lower viscosity and high fluidity, the resin reflows back to the print area more quickly, reducing overall print time.

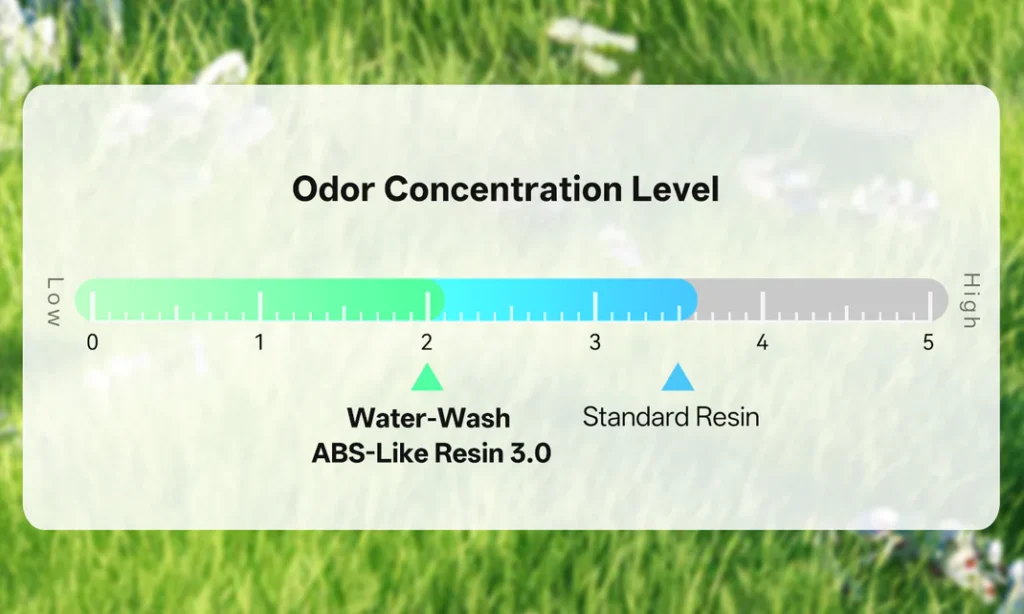

A fresh and more pleasant printing experience.

Low odor and non-irritating, creating a more comfortable printing environment.

It is compatible with all LCD/DLP printers that use 405 nm UV light curing technology and works best with Anycubic LCD printers

Preparations

_____________________________________________________________________________________________________________________________________________________________

Print Parameters

_____________________________________________________________________________________________________________________________________________________________

Physical Properties

_____________________________________________________________________________________________________________________________________________________________

Mechanical Properties

_____________________________________________________________________________________________________________________________________________________________

Post-processing-1

_____________________________________________________________________________________________________________________________________________________________

Post-processing-2

_____________________________________________________________________________________________________________________________________________________________

Printer Mode

Layer Thickness

Exposure Time

Light-Off Time

Bottom Exposure Time

Bottom Layers

Z Lift Distance

Z Lift Speed

Z Retract Speed

Photon Mono M7 Max

0.05 mm

2 s

0.5 s

30 s

5

8 mm

6 mm/s

6 mm/s

Photon Mono M7 Pro

0.05 mm

2.6 s

2 s

30 s

5

5 mm

8 mm/s

8 mm/s

Photon Mono M7

0.05 mm

2.2 s

1 s

35 s

4

8 mm

6 mm/s

6 mm/s

Photon Mono 4 Ultra

0.05 mm

2.6 s

1 s

30 s

5

5 mm

8 mm/s

8 mm/s

Photon Mono 4

0.05 mm

2.8 s

1 s

30 s

5

6 mm

4 mm/s

6 mm/s

Photon Mono M5s Pro

0.05 mm

3.6 s

1 s

35 s

5

8 mm

6 mm/s

6 mm/s

Photon Mono M5s

0.05 mm

3 s

0.5 s

25 s

5

8 mm

6 mm/s

6 mm/s

Photon Mono M5

0.05 mm

2.8 s

1 s

25 s

5

8 mm

6 mm/s

6 mm/s

(1) Before use:

Shake the liquid resin before use. Clean the resin tank and the molding platform to keep the bottom of the resin tank in good condition for light transmission.

(2) When using:

Unscrew the cap and add it to the resin tank according to the equipment requirements. Select the correct print parameters and settings for printing.

(3) After use:

After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves; ethanol(≥95%), lactate, or isopropyl alcohol cleaning solution;

(4) Post-processing steps:

A. Remove the printed model from the molding platform with a blade.

B. Submerge the model in the cleaning solution, rinse or ultrasonically wash, then take out and drain; ANYCUBlC Wash and Cure machines are suggested to ensure better effect.

C.Proper processing, such as removing support, polishing, coloring, etc.

At Sky Heights, we specialize in innovative 3D printing solutions and high-quality accessories. Our mission is to bring your ideas to life with precision and creativity, offering cutting-edge technology for a wide range of applications. Whether you’re a hobbyist or a professional, Sky Heights has the tools and expertise to elevate your projects to new heights.

Reviews

There are no reviews yet.